You could be forgiven for becoming completely wrapped-up in the possibility of cooling your home without an energy source or refrigerant. In fact, getting-wrapped up—quite literally—is exactly what two University of Colorado (UC) scientists believe may hold the key to mass producing amazingly efficient and positively affordable home cooling.

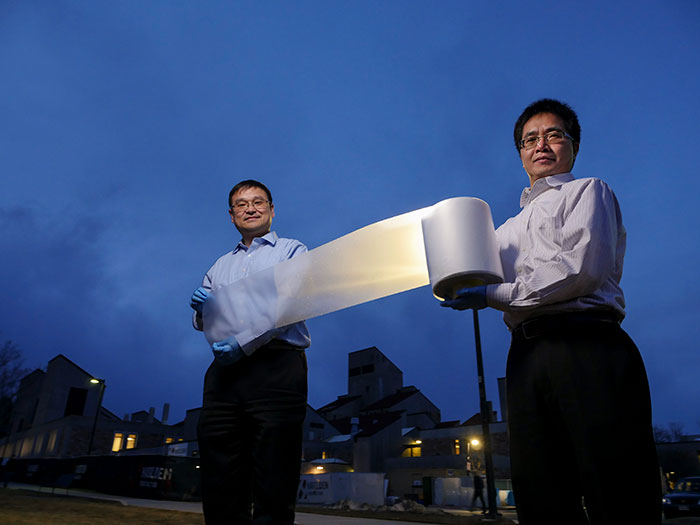

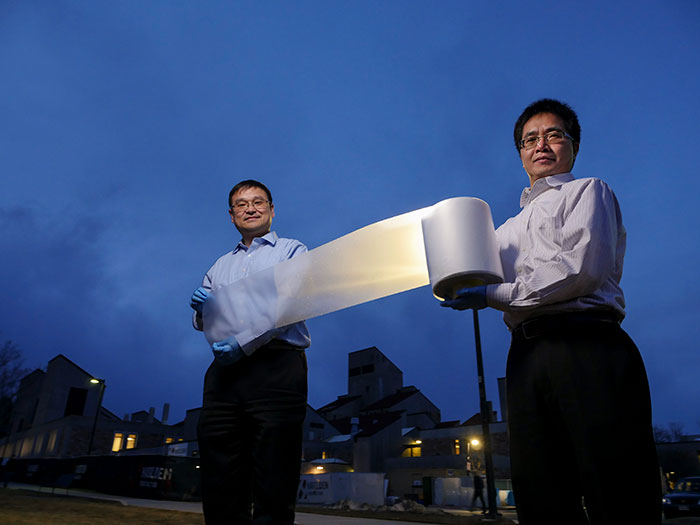

Ronggui Yang, Ph.D., and Xiaobo Yin, Ph.D., professors and researchers at UC’s Department of Mechanical Engineering, have invented a super-thin, semi-transparent material that looks like plastic wrap and takes advantage of a natural phenomenon called “radiative infrared cooling” to cool down whatever surface is directly below it.

It’s an ingenious approach that draws natural inspiration from nature itself–more specifically, how the earth cools off at night after being bombarded with solar radiation all day.

Catching a Good Reflection

When the sun basks an object in light, three things can happen with different wavelengths of light: They can be reflected, transmitted or absorbed, depending on the properties of the material the light is striking. So here on earth, on a clear night, the planet cools itself passively by bouncing infrared (IR) light (which builds up during daylight) back out beyond the earth’s atmosphere.

In 2014, a team of Stanford University researchers developed a seven-layer material that could cool objects by reflecting heat-bearing IR light back into space. Fast forward to 2017, and Yang and Yin’s research at CU followed a similar line of thinking, only this time with a simpler composite using polymethylpentene—a commercially available see-through plastic—as a foundation.

Two key components help CU’s material really shine (pun intended): A silver reflective coating added to the back of the film, and tiny (eight microns in diameter) glass beads mixed into the polymer before it’s drawn into sheets. When sun hits the film, infrared light—thanks to the precisely sized beads—is reflected back into space, and the silver backing helps bounce remaining incident sunlight back through the plastic (and away from the surface underneath).

The science, then, uses common materials to create a most uncommon result: More than 95 percent of the sunlight that hits CU’s materials bounces off of it.

Making Dollars and Sense

Despite requiring no power and being just about as thick as aluminum foil, CU’s material has promise to be a cooling powerhouse.

Field testing found that about it could create a cooling effect of about 110 watts per 11 square feet over a 72-hour period (night and day), about the same amount of energy generated by a typical solar panel used over the same timeframe. Considering how much electricity is devoted to household air conditioning—$29 billion worth annually in the U.S. alone—it becomes clear just how valuable CU’s material could ultimately prove.

Gang Tan, a co-author of the team’s research paper and associate professor at the University of Wyoming, described its potential this way: “Just 10 to 20 square meters of this material on the rooftop could nicely cool down a single-family house in summer.” And by “nicely cool down,” he means maintaining a comfortable 68 degrees inside the home while the mercury is hitting near 100 degrees outside it.

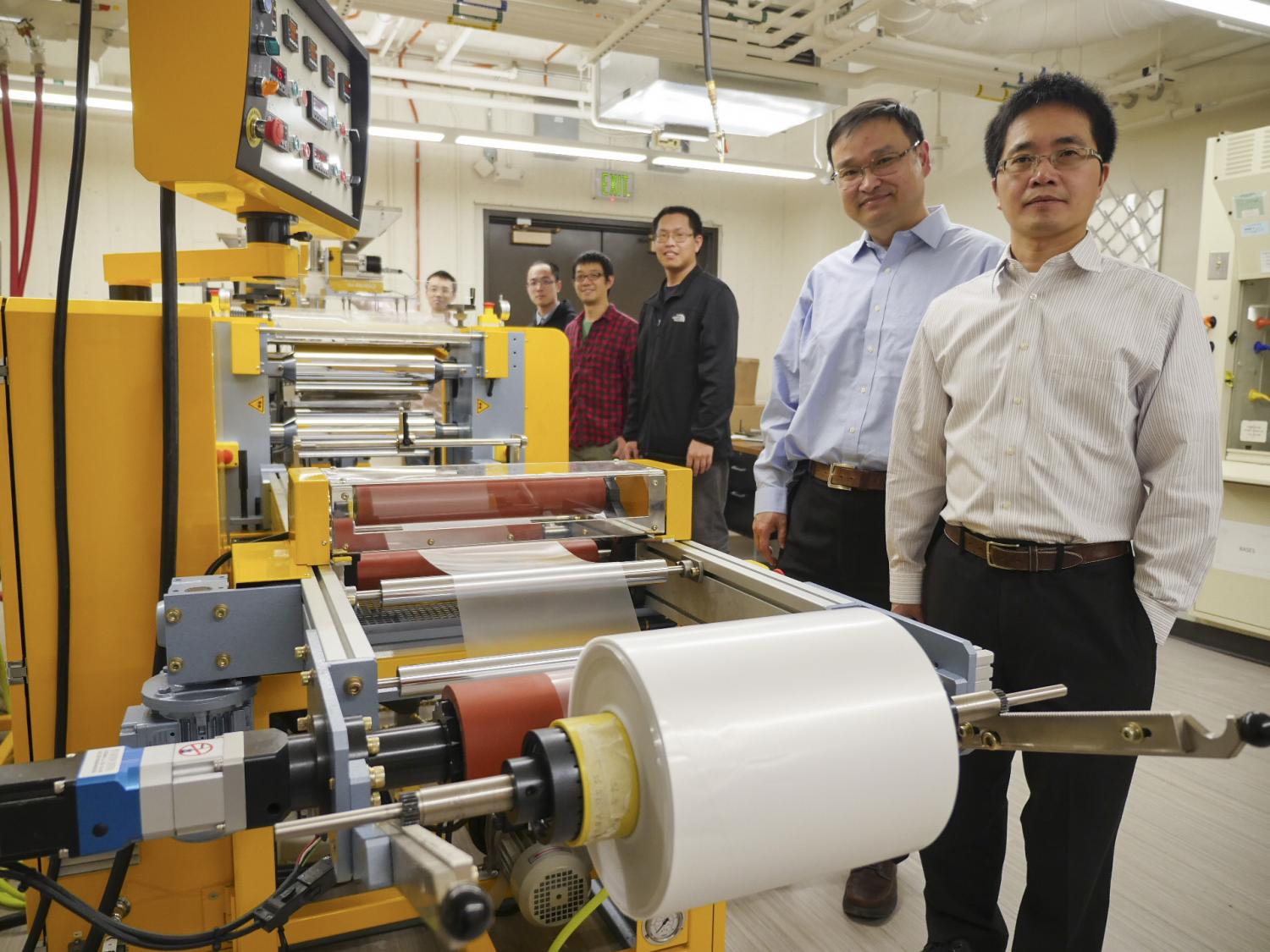

For the material to prove practical in the long-run, though, it’ll have to be mass produced affordably. The research team believes the reflective film could be manufactured in bulk using a standard roll-to-roll process for just $.25 to $.50 per square yard.

That attractive pricing may have contributed to the team’s decision to move forward with a larger, 200-yard demonstration project and to apply for technology patents. At that production price, the material becomes a more viable option for not only home cooling, but as a tool for improving the output of solar panels (which often lose efficiency when they overheat) or even to cool thermoelectric power plants (which today use water and energy to cool machinery).

“The key advantage of this technology is that it works 24/7 with no electricity or water usage,” said Yang in an announcement about the research. “We’re excited about the opportunity to explore potential uses in the power industry, aerospace, agriculture and more.”

What other ways could this innovation become a “cool wrap” for “hot stuff”?

The Innovation, Inspiration & Ideas blog was created to share stories and profiles of companies, products and individuals creating innovation in business through inventive material solutions. For more information on why we launched it, read our blog introduction.

Also in Industry Inspiration:

Using Carbon Dioxide to Make Plastics

in Industry InspirationScientists at Rutgers have developed catalysts that can convert carbon dioxide into plastics, resins, fabrics and more. Since carbon dioxide has been identified as a major cause of… Read More

Edible Water Bottles: the next big thing?

in Industry InspirationEdible water bottles could be in your future thanks to London-based startup Skipping Rocks Lab. Their first product, Ooho, makes you rethink “water on the go.” The idea behind Ooho… Read More