Hydrogels have left more than just a watermark on the pages of materials science history, being used in everything from diapers and cosmetics to drug delivery and flood control. Not bad for substances that live in perpetual limbo: After all, they’re not quite a liquid, and not quite a solid, but instead occupy a squishy middle ground between them.

Researchers at Japan’s Hokkaido University, though, recently discovered an inventive way to help hydrogels escape their reputation for being “soft” or “jelly-like.” By merging woven fibers with hydrogels, Hokkaido scientists discovered that they could create a material with incredible strength—as in, five-times-stronger-than-carbon-steel strength.

Leveraging the Matrix—and Creating a Stronger Bond

Hydrogels are advanced polymers built to achieve one of two basic—yet opposite—tasks: To let liquid in or to keep it out. Through their layered, lattice-like structures (called viscoelastic networks), hydrogels can expand to hold molecules or cells and contract when those molecules or cells are released.

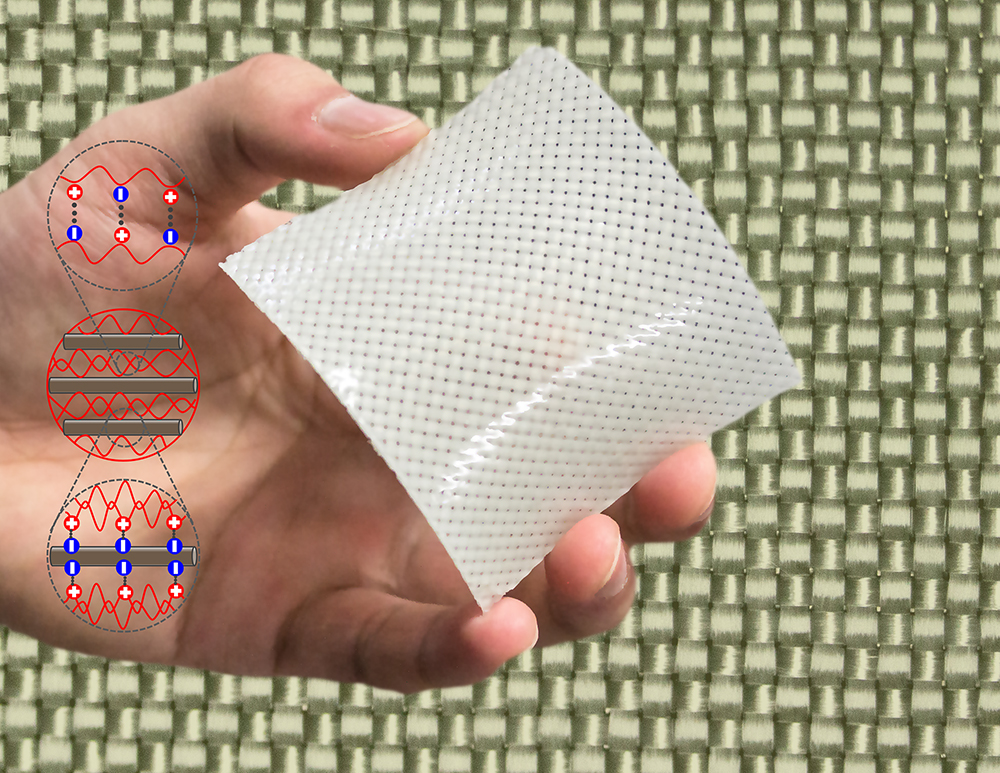

That unique ability to swell or shrink has offered material scientists an ideal medium, but those benefits have traditionally come at a cost of limited strength and durability. The new composites created by Hokkaido scientists overcome those limitations by integrating a polyampholyte (PA) gel they previously developed with a glass-fiber fabric. The end result is a material (called a “fiber-reinforced soft composite”) that’s super-strong, but still very pliable.

The Hokkaido team theorizes that the dynamic ionic bonds formed between the hydrogels and fiber are what create the composite’s tensile strength—or, put another way, it’s “synergistic toughening.” Breaking its bonds, researchers discovered, requires considerably more energy than that required to destroy either glass fibers or hydrogels independently.

It’s a marriage made in composite heaven. The two components are, in quite literal terms, stronger together than they are apart.

Testing the Real Mettle: Putting Composite Hydrogels to Work

Hydrogels’ typical benefits for consumer products like diapers (for absorption) or cosmetics (for hydration) are readily apparent. In more leading-edge applications, hydrogels are being analyzed for their potential in helping in everything from the fight against cancer to advanced energy storage.

So it’s easy to imagine yet another layer of benefits being realized when material scientists and engineers have access to a composite, next-generation hydrogel that offers both greater-than-steel strength and considerable environmental appeal.

The Future of Hydrogels

“The fiber-reinforced hydrogels, with a 40 percent water level, are environmentally friendly,” lead researcher Jian Ping Gong, PhD, explained in an announcement spotlighting her team’s work. “The material has multiple potential applications because of its reliability, durability and flexibility. For example, in addition to fashion and manufacturing uses, it could be used as artificial ligaments and tendons, which are subject to strong load-bearing tensions.”

What else might be possible with this super strong yet pliable material?

The Innovation, Inspiration & Ideas blog was created to share stories and profiles of companies, products and individuals creating innovation in business through inventive material solutions. For more information on why we launched it, read our blog introduction.

Also in Industry Inspiration:

Using Carbon Dioxide to Make Plastics

in Industry InspirationScientists at Rutgers have developed catalysts that can convert carbon dioxide into plastics, resins, fabrics and more. Since carbon dioxide has been identified as a major cause of… Read More

Edible Water Bottles: the next big thing?

in Industry InspirationEdible water bottles could be in your future thanks to London-based startup Skipping Rocks Lab. Their first product, Ooho, makes you rethink “water on the go.” The idea behind Ooho… Read More