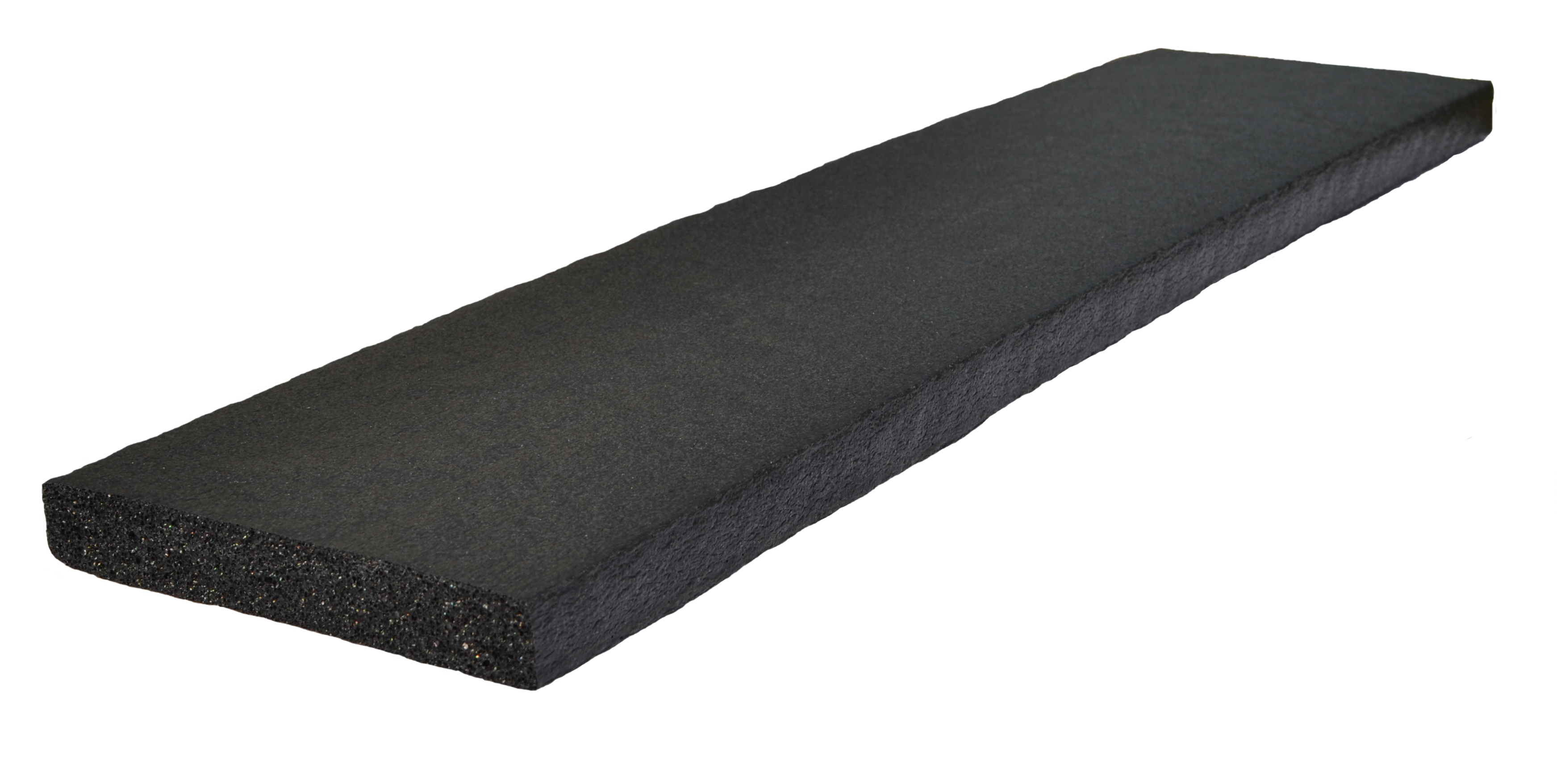

(Zebulon, NC) – For the last century, concrete installers have been using asphalt impregnated fiberboard (AIFB) as an expansion joint filler. Today, installers have a new choice in Nomaflex, a closed-cell polypropylene foam expansion joint filler and form, which has been evaluated by the American Association of State Highway and Transportation Officials (AASHTO). With positive industry feedback from the product’s initial introduction in select sizes last year, Nomaco is now introducing a full product line of 30 plank sizes in thicknesses ranging from ½” to 1” and widths from 3 ½” to 8”. Nomaflex will be available in sheet form in January 2017.

Nomaflex extends the service life of concrete by acting as a filler for full-depth expansion joints in sidewalks, streets, driveways, highways, airport runways and other applications. North Carolina-based Nomaco developed the product to solve common problems for installers, including concrete joint sealant failure, difficult installation, product breakage and on-going joint maintenance challenges.

“We are excited about the recently published, positive results of AASHTO APEL testing of Nomaflex, just in time for the roll out of our expanded sizes and introduction of sheet products,” said Larry Weimer, Technical Sales Manager for Nomaco. “No other competitive joint filler has been scrutinized and tested to the extent of this product.”

“Nomaflex is truly a game changer for the concrete market,” added Scott Edwards, Senior Vice President of Construction Products for Nomaco and 30

-year industry veteran. ”It’s simply the best expansion joint filler material on the market and the published APEL test results support it.”

Unlike AIFB joint filler products, Nomaflex is:

- An inherent bond breaker – When using sealants, no bond breaker is needed. This reduces cost and improves installation time. Nomaflex does not impede cure time.

- Waterproof – Nomaflex will not absorb water and will remain in place for years.

- Lightweight – Nomaflex weighs 75{f716f8da2bc6b8773d14b7ed437079b0125eeaf2794552f16b05c896ce8f16c3} less than competing asphalt impregnated fiberboard products, making it easy for one person to carry multiple bundles.

- Flexible – Nomaflex can be used as a form, bending to a 12-inch diameter if needed, but it is rigid enough to pass across wet pours without breaking.

- Inert – Nomaflex resists oils, gas, salts, acetone & other chemicals.

- Clean & Durable – Nomaflex has no sticky residue, does not leach and will not break or flake.

- Easy to Install – Nomaflex can be nailed or staked and is compatible with plastic edge caps to leave void for sealants.

- Re-usable & Recyclable – Nomaflex can be used multiple times as a form to reduce cost and waste. Made of polypropylene, it is also recyclable.

View video and installation photos of Nomaflex and learn more about the product, including sizes available at https://www.nomaco.com/product/nomaflex/.

The results of the AASHTO evaluation can be viewed on AASHTO’s Product Evaluation Listing at: http://apel.transportation.org/AASHTOEvaluated/ViewProduct/?id=119.

Established in 1979, Nomaco is a recognized leader in the design and extrusion of performance engineered foam products and components for a wide range of markets including construction, insulation, home furnishings, packaging, fitness & recreation and more.

Also in Construction:

Nomaco Wins 9th Consecutive Gold Safety Award

in ConstructionNomaco Inc. received its ninth consecutive Gold Safety Award from the North Carolina Department of Labor at the Department’s Annual Awards Banquet on Friday, May 31, 2019. The NCDOL Safety Awards… Read More

Manufacturing Day 2018

in ConstructionOn Friday, October 5th, 2018, Nomaco and our sister company, Vinventions, welcomed local students and educators… Read More