Building on work they first unveiled in 2015, a team of Colorado State University (CSU) researchers has discovered what they call an “infinitely” recyclable polymer that could offer considerable future potential for more efficient plastic recycling.

Many plastics require multiple chemical reactions to break them down into new raw material that can then ultimately be reassembled. Each of those steps consumes resources (think “time, energy, money”) and can sometimes create unwanted byproducts.

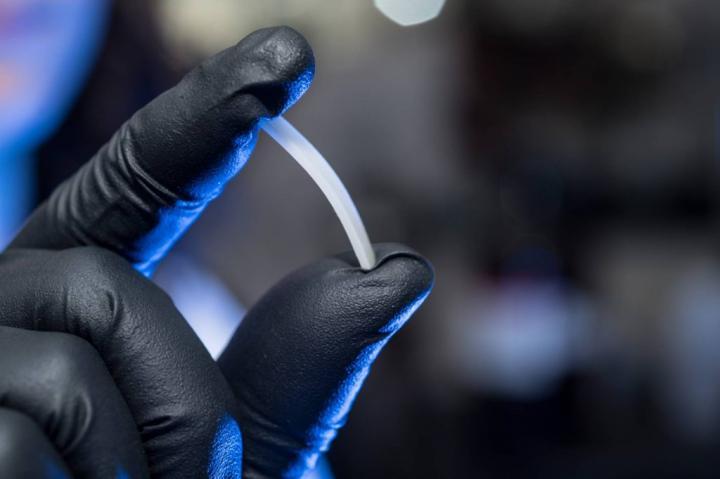

The CSU breakthrough, though, leverages a new kind of plastic that can be broken down into its native monomer and reconstructed—over and over—simply through using mild chemicals or heat and cooling as catalysts.

From One to Many—and Back Again

As manmade polymers, plastics are chained together from small molecules or “monomers.” CSU’s 2015 research started with an interesting and enterprising premise: Explore the use of a monomer (gamma-butyrolactone or “GBL”) that was considered impossible to chain together because of its unique thermal properties. Yet under precisely designed conditions, the CSU team was able to cool GBL and make a polymer from it [the aptly named “poly(GBL)”] and then reheat it to convert it back into its original monomer state.

The CSU team recognized the practical limits of its original research, since creating poly(GBL) required extreme cold that wouldn’t be practical at an industrial scale. In addition, their initial polymer was too soft and temperature-sensitive to make the grade.

Two years later, though, the team led by Eugene Chen, Ph.D. and Jianbo Zhu, Ph.D., found an ingenious way to get the rigidity and stability they needed.

Completing a “Circular Materials Life Cycle”

To construct the next generation of their infinitely recyclable polymer, Chen, Zhu and their colleagues altered one of their initial discoveries to “frame” a small, double-ringed molecule into a specific configuration. That new, stronger monomer was able to quickly join up with similarly formed neighbors—all at room temperature and with very little catalyst required. The end result is a heat-tolerant material that performs much like plastic.

More important, though, is its potential to be a truly recyclable material: Once in its polymer state, a catalyst used in mild lab conditions can take poly(GBL) back to its monomer form without the need for further purification.

The polymerizing and de-polymerizing creates what Chen terms a “circular materials life cycle.” And it’s one that requires no extreme temperatures (hot or cold), toxic chemicals or demanding lab processes.

“The polymers can be chemically recycled and reused, in principle, infinitely,” Chen said.

Helping poly(GBL) Take Shape

Grant funding from CSU Ventures is helping provide CSU’s team with the financial fuel to further advance their patent-pending polymer technology.

Polymer assembly will be a critical avenue of research, as the team continues both to further optimize its current approach to monomer synthesis and to explore other options for more cost-effectively chaining hydrocarbons together to form new polymers.

In addition to making the final result a less brittle plastic, the research team will also have to overcome a common challenge found along the substitute-for-petroleum commercialization pathway: Making its technology work at a viable and cost-effective scale while maintaining all the characteristics that make plastic so attractive (low weight, heat resistance, strength and durability).

“It would be our dream to see this chemically recyclable polymer technology materialize in the marketplace,” Chen said.

If that dream came true, which applications could most naturally capitalize on groundbreaking synthetic polymers?

Editor’s Note: Nomaco recycles our manufacturing scrap in-house or through third parties. Our polyethylene and polypropylene polymers are recycled using heat, moisture and cooling to return the material to a usable state.

The Innovation, Inspiration & Ideas blog was created to share stories and profiles of companies, products and individuals creating innovation in business through inventive material solutions. For more information on why we launched it, read our blog introduction.

Also in University Research:

Bees Provide Solution to Adhesive Failure

in University ResearchAdhesive can present a problem in high-humidity or low-humidity climates, but Georgia Tech researchers may have found a sticky solution by looking at honey bees. Bees collect pollen and carry… Read More

Stained Glass Technique Used to Create Bioactive Glass That Fights Bacteria

in University ResearchLeveraging a technique for making stained glass that dates back hundreds of years, a group of researchers at Aston University (Birmingham, UK) have developed a wholly modern weapon in the… Read More